JPS - editor

27 Giugno, 2023

Fernanda Debellian

Fernanda Debellian CSCP, CLTD, SCOR-P is the Regional Director for Central and South America and Solutions Architect for Sustainability at ASCM. She has over 20 years of experience in manufacturing, inventory management, logistics operations and distribution network design for multinational companies such as SCJohnson, Shell Lubricants, and NGOS in the Public Health space in Low and Middle Income Countries. As an APICS instructor, she has been involved in multiple capacity building initiatives in different countries with ASCM. Fernanda is an APICS Instructor and holds a B.S. in Chemical Engineering from the Pontificia Universidade Católica do Rio de Janeiro, and a M.Sc. degree in Management of Logistics and Production Systems from the École des Mines de Nantes, France.

Quando si inizia a parlare di sostenibilità – in un contesto di business – il discorso prende sempre una piega precisa: alla sensibilità per i temi quali il cambiamento climatico, lo sfruttamento dei minori, la sicurezza ed il benessere dei lavoratori, la diversity si sostituisce il freddo pragmatismo della bottom line. Chi paga per tutto questo?

Fernanda Debellian di ASCM ci fa riflettere su una prospettiva completamente diversa – e francamente più attuale – rispetto alla sostenibilità. In particolare nell’ambito della Supply Chain, ci introduce ai vantaggi – se non alla necessità – di pratiche più sostenibili per gestire meglio rischi, costi e preferenze degli investitori.

First of all we’d like to properly frame the topic. Can you please help us in defining correctly ‘Sustainability’?

FD: There’s a common misunderstanding that sustainability refers only to green solutions and taking care of the planet. But sustainability, actually, refers to solutions, processes and practices that takes into account not only the environment but also the ability of a company to continue to generate profit and economic value while respecting both the environment and society. So, a process or solution to be considered sustainable it needs to simultaneously generate economic value, with minimal or no-negative impact in the environment and society and communities around it.

How are the ethical, economic and ecological dimensions interconnected? How can the integration of these three dimensions into corporate strategy make a difference?

FD: These three dimensions are the pillars of what is known as the “Triple Bottom Line” and are also the pillars of sustainability.

The TBL terminology was created by John Elkington almost 30 years ago and the ASCM Dictionary describes as “an approach that measures the economic, social and environmental impact of an organization’s activity with the intent of creating value for both its shareholders and society.” This means that a company operating under the TBL concepts embeds sustainability into its strategy, operations and performance indicators. So companies integrating the three pillars from sustainability would typically not only measure profit, but also environmental metrics like water consumption, emissions and other social metrics.

We often see companies embracing sustainability into their strategy for multiple reasons like stakeholders’ demand, especially from the customer side, cost reduction as some sustainable practices may result in cost savings and increasing compliance requirements. We can also highlight the co-relation between risk and sustainability strategy. Companies with sustainability imbedded in their strategy tend to bear less risk as these are often operations designed with shorter supply chains, high adherence to compliance requirements and local – or not too far – sourcing.

We see a clear connection between Sustainability and Supply Chain: how can Supply Chain Management lead the way when it comes to Sustainability?

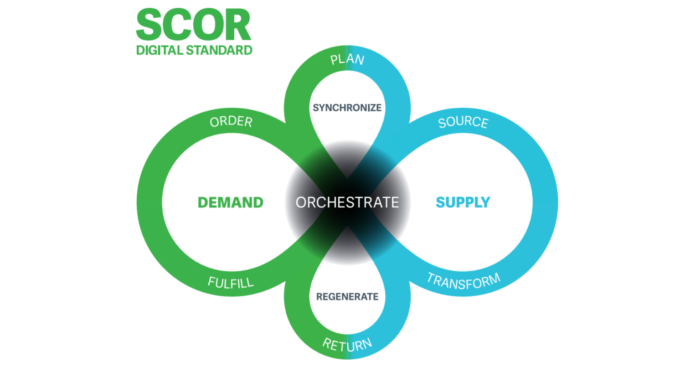

FD: The way supply chains plan, source, manufacture, fulfill and return its products has a direct impact in sustainability. Every sourcing strategy, network design, model optimization plan can either have a positive or negative impact in sustainability. When supply chain leaders realize how impactful these decisions are, it can be a game changer on the climate change equation.

The challenge is to educate and train supply chain professionals on designing supply chain networks that are optimized to generate profit while minimizing waste and emissions and respecting society – the key concept of sustainability. Supply Chain professionals have a key role as they can lead by example through the way they manage their operations.

Sustainability and Supply Chain are both trend topics and it might be hard for an organization or a professional to identify a single reference. What are the most relevant standards for Sustainability? Are there any specific ones for Supply Chains?

FD: My recommendation is to first get acquainted with the globally adopted sustainability frameworks. I would refer to the UN Sustainable Development Goals (SDGs) as a must for professionals to understand how their actions may contribute to the global goals. This is a high-level sustainability framework – not necessarily a standard – that has been widely adopted by companies when designing their sustainability strategy at a high level.

When we talk about tactics and operationalizing sustainability in the supply chain, I refer to the ASCM supply chain sustainability standards. These standards are free and have been widely adopted by hundreds of companies. The uniqueness of this standard is that it leverages the ASCM/APICS body of knowledge while also in alignment with other global frameworks like the Sustainable Development Goals facilitating the alignment of supply chain strategy with companywide sustainability strategy.

ASCM has the mission to “create a better world through Supply Chain Excellence”. What is ASCM Enterprise Certification for Sustainability? How does it embed the reference frameworks? How can it contribute to business performance improvement?

FD: The Enterprise Certification for Sustainability was created as a request from companies that wish to demonstrate their commitment to sustainability and excellency in the supply chain.

While the certification itself is a great achievement and some global companies are currently pursuing it, the greatest value is in the journey towards the certification. The company wishing to obtain the certification should have a minimum of 80% compliance with the ASCM sustainability standards. A thorough examination of the standards and its application leads to process improvements and increased sustainability, as most of the standards would have an aspect associated to environmental and social impact. By comparing the standards with the company’s “as-is” state, one can assess the gaps and what are the opportunities to increase performance and sustainability. The standards application on its own, even without the certification, is a powerful tool for self-assessment and embedding sustainability in the supply chain. I can point out to one example of a company that was looking for the sustainability certification, but because the standards are focused on supply chain excellency as well, a great opportunity in their S&OP process was uncovered during the certification journey. After the certification, the company took in a new journey to improve the S&OP process and ended up saving millions of dollars.

So, the certification journey will not only address sustainability themes, but may also uncover operational opportunities that lead to direct cost savings.

Are there successful examples of Supply Chain redesign from a Sustainability perspective?

FD: Yes, most examples we see now relate to shortening supply chains, in other words, bringing manufacturing and sourcing closer to consumer markets. In addition, embedding circular elements in the supply chain since the design phase (design for circularity) and the sourcing of materials that have been previously used (high % of recycled raw material) or sourced from other supply chains.

JPS è attivamente impegnata nell’ambito della sostenibilità. Proponiamo corsi di formazione e business simulation per comprendere ed approfondire questi temi. In collaborazione con ASCM, affianchiamo le aziende nell’assessment delle loro pratiche di Supply Chain e nell’individuazione di opportunità per renderle più sostenibili.

Per informazioni scrivi a info@jpsconsulting.it

Potrebbe interessarti anche

Get in touch

Iscriviti alla nostra Newsletter: ti promettiamo ogni mese un contenuto esclusivo sul mondo della Supply Chain, novità, interviste ed approfondimenti. Resta sempre aggiornato!

Download brochure

Scarica subito la brochure di JPS per conoscere la nostra realtà aziendale, le proposte che offriamo e i percorsi di formazione disponibili.